Ready-to-Install Solutions in New England

Electrical Wholesalers offers comprehensive ready-to-install electrical prefab services in the New England area. Our solutions can help you increase profits while reducing operating expenses on the job site. You can complete each job with more continuity while working more efficiently and minimizing completion times.

Our prefabrication solutions include pipe bending, pipe threading & cutting, strut cutting & assembly, and MC/Flex whips. We can design and prepare materials to your exact specifications. You benefit front ready-to-install supplies that help you cut down on waste. Place your order today by calling 781-875-8134. We serve the New England territory, including Massachusetts, Rhode Island, New Hampshire, and Connecticut.

Ready-to-Install Solutions We Offer

Pipe Bending

We can bend ½” to 4” EMT, IMC, rigid, aluminum rigid, and stainless steel Conduit into almost any configuration. Integrated with BIM Software through Revitand BendWorks®. Optimize the design of conduit runs for more efficient and accurate fabrication. Your pipes are bent, measured, and cut to their final length.

Pipe Threading & Cutting

We offer pipe threading service with pipe diameters ranging from ½” through 6”. We custom cut and thread to your specifications, and work with materials including intermediate metallic conduit, galvanized rigid conduit, PVC coated GRC (OCAL, ROB ROY, PERMA COAT), aluminum rigid conduit, and schedule 40 black pipe.

Strut Cutting & Assembly

We can cut strut to your precise specifications, kit your order, and bundle, store, and ship only the material you need, whenever and wherever you need it. Our process helps you save time, money, and stress during your project. Go directly from delivery to installation with burr-free cuts that require no post-processing.

MC/Flex Whips

Our custom-cut cable and luminary whips provide you with a valuable option for projects that require short lengths of cable. Whips come ready to install, pre-cut with connectors supplied, with configurable lead and tail lengths, and with or without anti-short bushings. Choose from a variety of configurations.

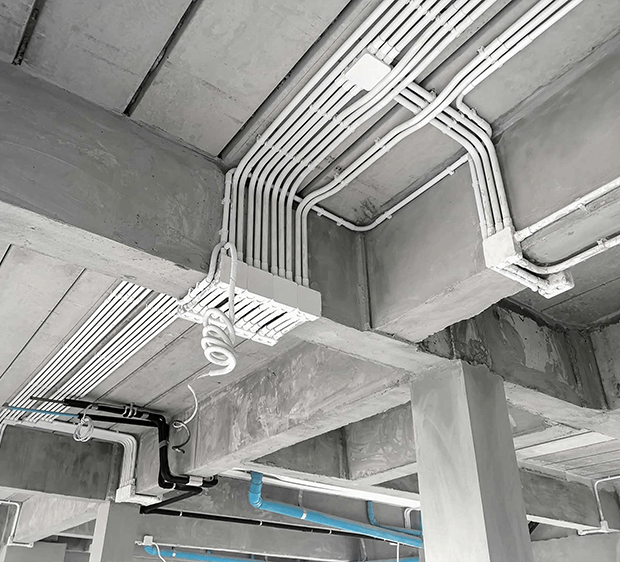

Our Prefabrication Process and Facilities

Our Prefabrication Process and Facilities

The Electric Wholesalers prefabrication facility is fully equipped with advanced tools and technology to handle high-end bending and cutting conduit, strut, and threading jobs. Our systems also customize MC whips for both boxes and fixtures, depending on the type of job you are currently working on.

Our team works with your team in a climate-controlled environment, where you have numerous options for prefabricating your materials. You can either provide your labor or allow our team to complete all fabrications for you. We have offices complete with Internet, office, equipment, and monitors that will enable you to view your CAD projects.

Packing, Loading, and Delivery

We provide rolling Pallets that you can use to pack, load, and deliver all materials to your site on your schedule. Your order arrives in pristine condition so that you can get straight to work. All orders are double-checked for accuracy to eliminate any errors.

If you need a professional workspace to design and build your product, a space to store your product, or product delivery straight to your worksite, Electrical Wholesalers can accommodate you at every stage of prefabrication.

Perfect for Repetitive Installations

Perfect for Repetitive Installations

Electrical Wholesalers electrical prefab solutions are perfect for projects requiring repetitive electrical installations. All pre-fabricated assemblies are labeled to match a detailed layout drawing. Any electrical project will profit from a ready-to-install system. The larger the project, the more your company benefits. We provide products for the following applications:

- Residential: apartments, military and campus housing, condominiums

- Hospitality: hotels, motels, casino resorts, conference centers

- Corporate: office buildings, warehouses, banks, high-rises

- Healthcare: hospitals, healthcare facilities, assisted living

- General Contracting: commercial and industrial projects

- Subcontracting: all types of subcontracting electrical jobs

Do you need to place an order for electrical supplies? Shop our online store and get your order started today. Take advantage of our electrical delivery service. We serve the New England territory, including Massachusetts, Rhode Island, New Hampshire, and Connecticut.